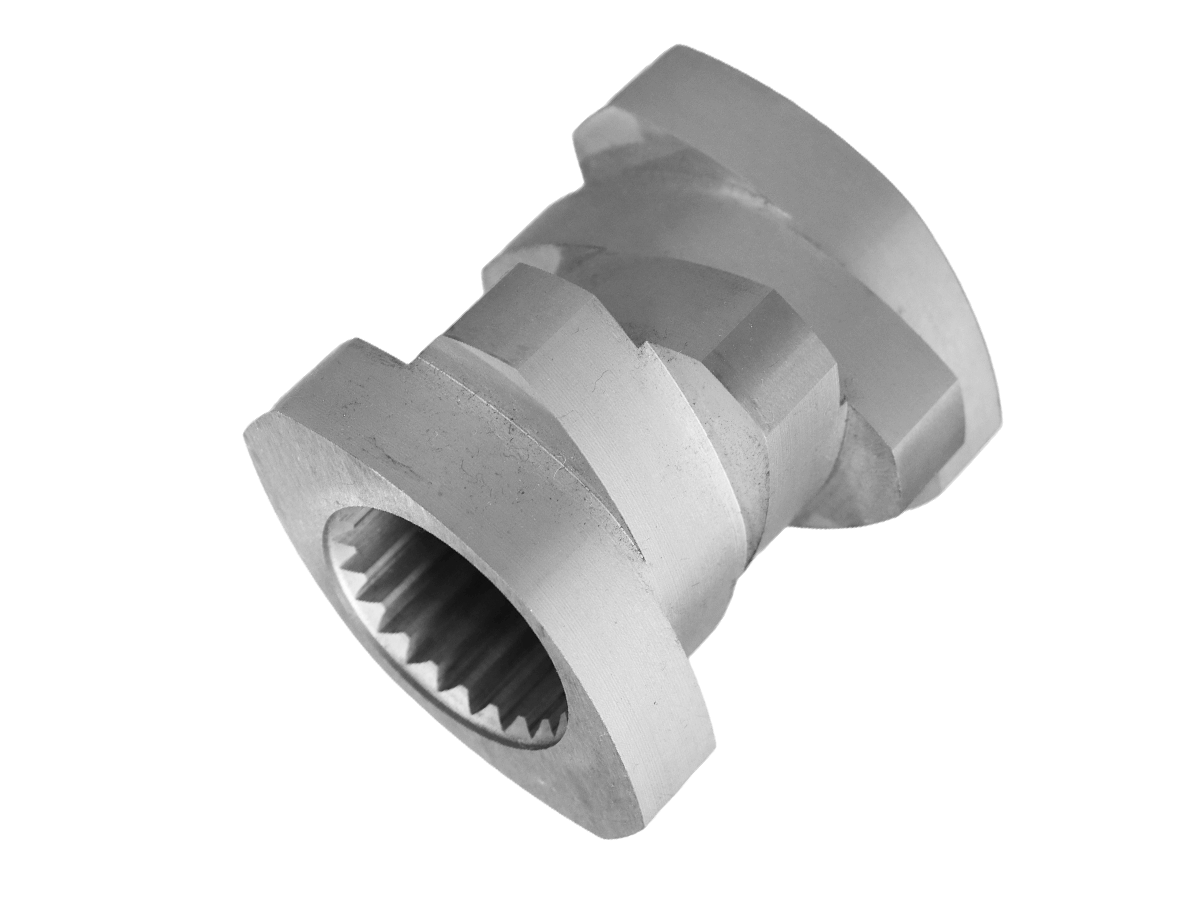

R-Kneading elements are divided according to offset angle:

30°, 45°, 60° . With the increase of the offset angle, the conveying ability of the material is gradually weakened, and the dispersive mixing ability is gradually increased.

R-Kneading elements are divided according to the kneading disc:

Narrow disc, standard disc, wide disc. With the increase of the width, the shear ability of the material is gradually increased, and the distribution mixing ability is gradually weakened.

Model: Φ 18 mm~Φ 400 mm

Material: WR5/WR7/WR13/Nickel based alloy

Performance: Wear resistant and corrosion-resistant

WR5: The carbide of WR5 is mainly composed of small dispersed spherical vanadium carbide, supplemented by an appropriate amount of chromium carbide. It has good wear resistance, excellent impact performance, and good anti peeling performance. Its service life is about three times that of 6542 material.

WR7: The carbides in WR7 are mainly small dispersed spherical vanadium carbide and chromium carbide, with a large number of carbides and the highest comprehensive wear and corrosion resistance, making it a high-end alternative to WR5.

WR13: It has both wear and corrosion resistance, suitable for the battery slurry industry.

Nickel based alloy: has good wear and corrosion resistance

1. Forward conveying materials

2. Plasticizing materials

3. Moderate shear force (related to offset angle and thickness of kneading disc)

Copyright © Ma'anshan Huawei Metallurgical Machinery Co., Ltd SITEMAP Technical Support:Chengguang Network